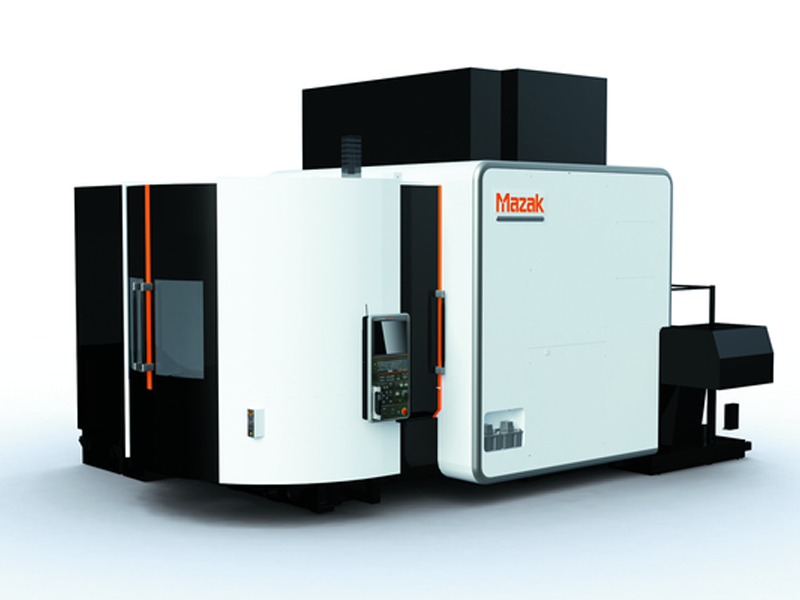

VORTEX e1060V/8

VORTEX 1060V/8 delivers high productivity by simultaneous 5-axis controlled machining and multiple surface machining.

VORTEX II Series

- 5-Axis Simultaneously Controlled Vertical Machining Centers.

- The Mazak VORTEX II series is designed to machine large work pieces such as aerospace components with complex contours with unsurpassed accuracy and efficiency. The unique tilting spindle design provides high accuracy as well heavy-duty machining capability thanks to the employment of backlash-free roller gear cams.

- High Performance Machining of Complex Workpieces.

Machine Specifications

| Standard Machine | Values | |

|---|---|---|

| CAPACITY | Maximum workpiece diameter | 1,250 mm |

| Maximum workpiece height | 1,250 mm | |

| X-axis stroke (saddle right/left movement) | 1,875 mm | |

| Y-axis stroke (column back/forth movement) | 1,060 mm | |

| Z-axis stroke (spindle up/down movement) | 1,345 mm | |

| SPINDLE | Spindle speed maximum (standard spec.) | 10,000 min-¹ |

| ATC & TOOL MAGAZINE | Tool storage capacity (standard) | 40 tools |

| Tool storage capacity (option) | 80,120 and 160 tools | |

| Tool shank type | MAS BT50 CAT 50 (DIN 50) | |